C2 PROJECT

C2 Photo Album

album:February 2018

Linda shunts wagons at the Moelwyn Tunnel worksite in the horrendous weather that we experienced for most of the weekend.

Erle carefully set up the brake weighshaft on the Bridgeport mill, and cleaned up the keyway which was corroded. We'll need to make a custom sized key now, but at least it will be a good fit.

The new brackets for the yaw damper are now welded to the inside of the rear bufferbeam.

Andrew and Dave 2 ream out the first of the front bufferbeam fixing holes. We've had custom fitted bolts made to hold the bufferbeams in place.

First of the custom bolts fitted on the front buffer beam. We'll weld around the heads and grind them flat.

Lubricator worksplate - I'm not sure if this was a spare or the one fitted to the fireman's side of the loco.

Lubricator worksplate - this was the steam oil lubricator on the driver's side.

We saw a little bit of blue sky on Friday morning, illuminating the snow on the mountains. Heavy rain has flooded the reclaimed land - it must have looked like this before William Madocks built the cob.

A pile of parcels waiting for our arrival. These included Iglidur bushes and a tension spring for the brakegear, custom fitted bolts with nuts and washers for the bufferbeam fixings, some new milling cutters, and a new item of merchandise.

Parallels set up to measure the tender horn mounting plates.

Dave measures the tender horn mounting plates

Dave measures the tender horn mounting plates

Welsh Slate coasters, with the Chinese Forestry Railways (and C2 Project) logo engraved into them. These will be available for sale soon.

Andrew welded in the platework for the battery box in the tender. This will provide power for the loco lighting; one day we hope to replace or resuscitate the turbogenerator too.

Battery box surround welded in place. The floor of the box will be wooden.

The bufferbeam fixing bolts were designed to be welded in place and ground flush afterwards.

The new front bufferbeam isn't coming off again! The six large fitted bolts are now welded in place, and the join in the footplating is welded up too. Soon we'll get the red paint out again!

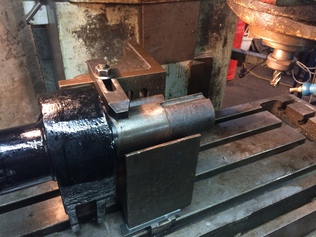

Milling out the keyway in the brake weighshaft

Milling out the keyway in the brake weighshaft

The steam brake crank, with the new return spring bolt fitted.

The steam brake crank, with the new return spring bolt fitted.

Return spring bolt for the steam brake crank.

Andrew and Dave 2 ream holes in the rear buffer beam

Andrew and Dave 2 ream holes in the rear buffer beam

Andrew and Dave 2 ream holes in the rear buffer beam

Dave 1 supervises!

Andrew and Dave 2 ream holes in the rear buffer beam

The rear bufferbeam welded in place. The two remaining hexagonal bolts seen here will be replaced by eyebolts to hold the loco-tender safety chains.

Lubricator worksplate - The one sold to the NG15 group which was originally one of the spares obtained from Dahuichang.

Dahuichang Dog

Dahuichang Dog

Dahuichang Dog

The Gib key has been ground to the right fit laterally, but still needs the top and bottom faces fettling to give a good fit to the brake weighshaft and the crank.

Components for the battery box door hinges

Erle also made the battery box door, seen here in front of the frame cutout which will give access to the battery box.

Construction of the new double Fairlie 'James Spooner' has commenced, with parts of the frame cradle seen here in the foreground. Will it be finished before the C2? Probably...

It appears that some additional parts have been ordered - will the mighty Square ride again too?

It appears that some additional parts have been ordered - will the mighty Square ride again too?

Dave 1 prepares to mill the back face of a tender horn angle on the Wanderer mill.

Meanwhile Paul was milling a slot along the working edge of the horn angle on the adjacent Bridgeport mill.

Dave 1 drills out the press tool for fitting the plastic bushes.

One of the new brake block carriers with its plastic bushes fitted.

The press tool pin inserted through the bushes gives an idea of what this interface will look like when we've finished all the brake pins.

After several hours patient work, Erle achieved an excellent fit.

A selection of brake gear components with the Iglidur bushes now fitted. This type of plastic bush has been used on Ff&WHR carriage brakegear for 20 years, leading to a huge reduction in the maintenance required.

One of several configurations of measuring equipment used to align and check the tender horn angle dimensions.

Our tender frames in the sunny but cold works yard, for a little welding. They are surrounded by green diesels, from left to right: Conwy Castle's cab, Upnor Castle, Vale of Ffestiniog, Moel-y-Gest. Does anyone remember the Conwy's 'Bertie Bassett' livery? The remains are just visible here.

Colin turning alignment dowels for the tender horns.

Erle used the baby Myford lathe to make some hinge pins.

Dave 2 reamed out the bearing cup for the tender handbrake column, which will need to be welded to the tender frames soon.

The Moelwyn Tunnel works trains were heavy ballast hoppers this week, which required more powerful traction. 1979-built double Fairlie 'Earl of Meirioneth' was rostered.

We had a few bursts of sunshine on Thursday: the 'Square' is seen here with freshly ballasted track in the background. This loco will be withdrawn in a couple of months, to be replaced eventually by the new 'James Spooner'.

Dave starts the small holes in the tender horn angles using a centre drill.

Tender horn angles bolted temporarily in place for measurements.

Checking the squareness of the newly machined faces on the tender horn angles.